Ensuring Excellence: Our Comprehensive Quality Control Procedures for Electronic Components

1. Material Inspection: The Foundation of Quality

Quality begins with the materials. Our team meticulously inspects every incoming batch of electronic components to ensure they meet our strict specifications. This involves thorough checks for authenticity, durability, and compliance with industry standards. By starting with high-quality materials, we lay the foundation for reliable and long-lasting electronic components.

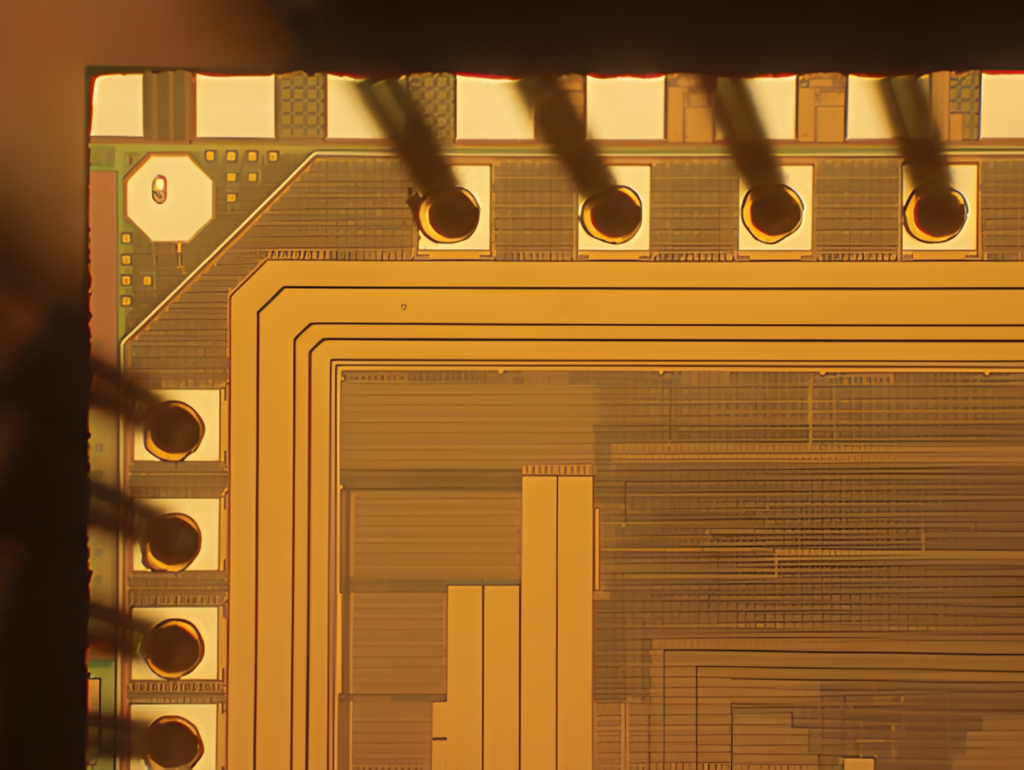

2. Visual Inspection: Precision at a Glance

Visual inspection is a critical step in our QC process. Our experienced technicians conduct detailed visual examinations to identify any visible defects, irregularities, or imperfections. This meticulous visual inspection ensures that each electronic component not only meets our high-quality standards but also presents a polished and professional appearance.

3. Decapsulation Test: Unveiling the Core

As part of our commitment to transparency and quality, we conduct decapsulation tests on select electronic components. This process involves carefully removing the outer layers of a component to expose its core. By doing so, we can inspect the internal structure for any anomalies, ensuring the integrity of the component’s design and construction.

4. Advanced Testing Technologies: Precision at Every Step

Our commitment to quality extends beyond the initial inspection. We leverage state-of-the-art testing technologies to evaluate the performance, reliability, and functionality of each electronic component. From environmental stress testing to functional testing, we leave no stone unturned in guaranteeing that our components meet or exceed industry standards.

5. Functional Test: Ensuring Peak Performance

Functional testing is a core element of our QC procedures. Each electronic component undergoes rigorous functional testing to verify that it performs according to specified parameters. This includes testing for accuracy, speed, and compatibility with other components. Only components that pass these stringent functional tests move forward in the manufacturing process.

6. Automated Inspection: Efficiency and Accuracy

To enhance efficiency and accuracy, we incorporate automated inspection processes into our QC procedures. Advanced machines and software are employed to conduct precise measurements and detect any deviations from the set parameters. This not only speeds up the inspection process but also minimizes the margin of error, ensuring consistently high-quality electronic components.

7. Traceability: Accountability at Every Stage

We prioritize traceability throughout our manufacturing process. Each electronic component is assigned a unique identifier, allowing us to trace its journey from raw material to finished product. This meticulous tracking system enables us to identify and rectify any issues swiftly, ensuring that only flawless components reach our customers.

8. Continuous Improvement: Learning from Experience

Our commitment to quality doesn’t stop with the production of electronic components. We embrace a culture of continuous improvement, learning from each manufacturing cycle. Regular reviews and feedback sessions help us refine our QC procedures, incorporating the latest technological advancements and industry best practices.

9. Compliance with Industry Standards: Your Assurance of Quality

At G-jay electronics, we adhere strictly to industry standards and certifications. Our QC procedures align with the latest regulations and guidelines, giving our customers confidence in the reliability and safety of our electronic components.

Conclusion

When you choose G-jay electronics, you’re choosing a partner committed to delivering electronic components of the highest quality. Our comprehensive QC procedures, including visual inspection, decapsulation tests, and functional testing, coupled with a dedication to innovation and customer satisfaction, make us a trusted name in the industry. Contact us today to discover how our electronic components can elevate your projects to new heights of performance and reliability.